The Products BKOYIA Offers You

BKOYIA is a leading manufacturer specializing in the development and production of wooden doors. Our commitment to quality has made us a global supplier of wooden door solutions.

Our product lineup consists of three distinct series:

The collection is eco-friendly and low to mid-budget. The interior is made of wood blocks and the exterior is made of MDF and melamine paper. If you are decorating your home or hotel, he will be your best choice

melamine door-BM-140

melamine door-BM-148

melamine door-BM-142

melamine door-BM-150

melamine door-BM-146

melamine door-BM-140

melamine door custom made

We provide 3 wooden door series: the standard size is 2100mm*900mm*200mm, which will fit the size of most areas.

In addition to our standard products, we are also proud to offer customized services tailored to individual processing requirements. Customize your own according to the size, style and material you provide.

Tailor your door’s style to match your vision. From modern to classic, we craft doors that uniquely embody your personal aesthetic

Every space deserves a perfect fit. We customize door sizes to meet your specific dimensions, ensuring flawless integration into your home or office

Choose your hardware to enhance your door. Choose from a range of high-quality door locks and hinges to add the finishing touches to your design

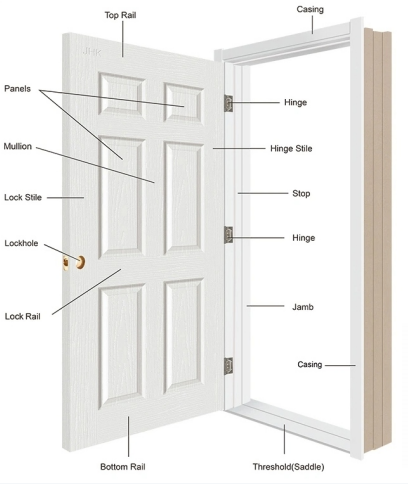

Wooden door structure combination

Door Slab: The main, flat part of the door, which can be solid wood or a composite with a wooden veneer. It’s the primary component that swings open and shut.

Frame: The framework that surrounds and supports the entire door system. It usually consists of the head, jambs, and threshold.

- Head: The horizontal piece forming the top of the frame.

- Jambs: The vertical sides of the frame.

- Threshold: The bottom part of the frame; it can be made of wood or other materials for durability.

Panels: Many wooden doors have panels – raised or recessed sections – adding to their visual appeal and structural integrity.

Rails and Stiles:

- Rails: Horizontal elements of the door’s structure.

- Stiles: Vertical elements, with the “lock stile” being on the lock side and the “hinge stile” on the hinge side.

Core: In some doors, especially exterior ones, the core might be filled with insulation materials for better energy efficiency.

Hinges: Metal pieces that attach the door to the frame, allowing it to swing open and closed.

Knob/Lever and Lockset: The handle and locking mechanism. There are various styles and security levels to choose from.

Peephole, Mail Slot, and Other Accessories: Depending on the door’s purpose, additional components like peepholes, mail slots, or decorative glass inserts might be included.

Weatherstripping: For exterior doors, weatherstripping is crucial for sealing against drafts and moisture.

Finish: The final surface treatment, which could be paint, stain, or varnish, that protects the wood and enhances its appearance.

Choose your material

Bridge tunnel mechanics plate

Principles of bridge tunnel mechanics plates: Principles of arch bridge tunnels

Features: It has the characteristics of high filling degree, sound insulation, heat preservation, fire prevention, environmental protection, etc. It is the door core material of high-end wooden doors. Applicable people: suitable for all kinds of people.

honeycomb paper

Principle: Principle of natural honeycomb structure Characteristics: It has the characteristics of light weight, low cost, high strength, smooth surface and not easy to deform, sound absorption, heat insulation, no pollution, etc., in line with the modern environmental protection trend. Applicable people: suitable for people with limited budget and renting houses.

solid wood

Pure solid wood door: Made of natural logs as the door core and processed by drying. Common woods include walnut, cherry, pear wood, etc. Pure solid wood doors have high requirements on production technology and require good dehydration and degreasing, otherwise they will easily deform and crack.

block

Attributes: It is a solid wood board filling, generally used for wooden doors. Features: Wood blocks are used as fillers. The processing accuracy of the thickness directly determines the flatness of the door. The production is cumbersome. Applicable people: Suitable for middle-class consumers.

Door Locks -------Hinges-------Door Stoppers

About hardware

What is hardware

Door Locks:

- Affordable Price: Traditional door locks are highly cost-effective, offering reliable security at a fraction of the cost of advanced locking systems.

- Easy Installation: These locks are straightforward to install, requiring only basic tools like a screwdriver, making them accessible for DIY installation.

- Simple Operation: Traditional locks are free from technical complexities, ensuring hassle-free, dependable use right after installation.

- Exclusive Key Access: Each lock is designed for a specific key shape, ensuring that only authorized keyholders can gain access.

Hinges:

- Easy Installation and Replacement: Compared to other hinge types, these are simpler to install and replace, making them a practical choice for various applications.

- Enhanced Durability: Ball bearing hinges offer smoother swing action and higher durability, reducing wear and tear, thus extending the lifespan of both the hinge and the door.

- Structural Support: These hinges provide enhanced structural support, distributing the door’s weight evenly, ensuring smooth and aligned movement, and minimizing warping and sagging. They are particularly suitable for wide doors.

Door Stoppers:

- Protecting Door and Wall: Door stoppers are essential in preventing damage to both doors and walls from forceful opening, maintaining the overall appearance of the space.

- Propping Doors Open: Certain door stoppers allow doors to stay open, useful in high-traffic areas or commercial settings like shops and restaurants.

- Adding to Decor: Door stoppers are not just functional; they can also enhance the decor. Available in various finishes, they can complement and add to the aesthetics of a room.

Melamine door production process

1. Design and planning: Determine the design, size and style of the door according to needs.

2. Material preparation: Choose appropriate medium density fiberboard (MDF) as the base material.

3. Base material processing: Cut the MDF to the required size and polish it to ensure a smooth surface.

4. Melamine veneer: The melamine film is bonded to the MDF board through a hot pressing process to form a wear-resistant and water-resistant surface.

5. Edge treatment: The edges of the door are edge-sealed to improve durability and aesthetics.

6. Hole processing: According to design needs, lock holes, hinge holes, etc. are processed on the door panel.

7. Surface decoration: According to customer requirements, additional surface decoration may be carried out, such as painting, spray painting, etc.

8. Assemble hardware accessories: Install door locks, hinges and other hardware accessories.

9. Quality inspection: After completing all processes, conduct quality inspection on the door to ensure that it meets the established standards.

10. Packaging and Logistics: Doors that have passed the inspection will be properly packaged and prepared for transportation.

Advantages of melamine doors

1. Price advantage: Compared with solid wood doors, melamine wooden doors usually have a more affordable price, making them a cost-effective choice suitable for families or projects with limited budgets.

2. Process characteristics: The melamine door uses medium density fiberboard (MDF) as the base material, and the surface is covered with melamine resin. Through high temperature and high pressure treatment, the door surface has good wear resistance, scratch resistance and waterproof performance.

3. Material advantages: Due to its special surface treatment, melamine wooden doors not only have good moisture-proof and mildew-proof properties, but are also easy to clean and are suitable for various use environments such as kitchens and bathrooms.

4. Diverse styles: The melamine surface can be printed into various wood grain patterns or other decorative patterns, which can imitate the appearance of solid wood doors and meet the needs of different decoration styles. From modern simplicity to traditional elegance, melamine wooden doors offer a wealth of options.

5. Environmental performance: Modern melamine wooden door manufacturers pay attention to environmental protection and ensure that the amount of formaldehyde released during the production process meets national safety standards, providing users with a healthier living environment.

What are the advantages of ecological doors?

What are the advantages of ecological doors?

Harmicis to the human body:

The ecological door is a product derived from the concept of ecological homes. The key to ecological home is environmental protection and health. It belongs to the standard of green home. Therefore, ecological doors are harmless products of the human body.

Can recycling:

The ecological door is a door made of recyclable materials. This kind of material has no harm to nature, thereby reducing the pollution of the ecological environment and conforming to the concept of sustainable development and protecting the ecological environment.

The shape is simple and beautiful:

Compared with the traditional wooden door color style, the style of the ecological door is novel, the color is diverse, and it is suitable for the current popular modern style, minimalist style, minimalist style and so on.

Environmental health:

The ecological door eliminates environmental protection and health issues that people worry about, and will not produce harmful substances such as formaldehyde, toxic glue, and paint that may contain wood products.

More practicality:

Ecological doors of fire prevention, corrosion resistance, good sealing, and never fade can provide consumers with more practical functions. For home life, they can better enjoy the beauty and practicality of the ecological door.

Melamine wood edge sealing process

1. PUR edge sealing technology: Use PUR edge sealing glue to provide stronger adhesion, ensure the firmness and durability of the edge sealing, and effectively prevent cracking and falling off of the door edge.

2. Waterproof and moisture-proof: The edge sealing treatment can effectively prevent water and moisture from intruding into the interior of the door, reducing the risk of the wooden door deforming due to water absorption and expansion.

3. Improve durability: Good edge sealing can protect the door edge from damage and extend the service life of the door.

4. Improved aesthetics: Fine edge sealing can make the appearance of wooden doors neater and more beautiful, and improve the overall decoration style.

5. Easy maintenance: The surface of the wooden door after edge sealing is smoother, making it easier to clean and maintain.

6. Environmental adaptability: High-quality edge sealing materials and technologies can make wooden doors better adapt to various environmental changes, including fluctuations in temperature and humidity.

7. Color and material matching: The diversity of edge sealing materials can ensure a perfect match with the color and material of the wooden door body and maintain the unity of the design.

8. Sound isolation: Edge sealing is not only a visual requirement, it can also provide a certain sound isolation effect and increase privacy.

9. Environmental protection and health: Use non-toxic, environmentally friendly edge sealing materials to ensure a healthy indoor environment, especially suitable for places with high environmental requirements such as homes and schools.

10. Customized services: Provide customized edge sealing services. According to the specific needs of customers, the most suitable edge sealing materials and technologies are selected to meet personalized decoration styles and functional requirements.

Wooden door packaging process

1. Cleaning and inspection: Before packaging, make sure the surface of the wooden door is clean and dust-free, and check for any damage or defects.

2. Protect edges: Use foam or plastic corner protectors to cover the four edges of the door to prevent damage during transportation.

3. Packaging materials: Choose appropriate packaging materials according to the size and weight of the door, such as foam board, bubble film or shock-proof film.

4. Wrap the door body: Completely wrap the wooden door with protective materials to ensure that all sides are fully protected.

5. Closed packaging: Use tape or wrapping film to secure the protective material to ensure it does not loosen during transportation.

6. Marking and Labeling: Clearly mark packaging with information about the items contained, including warning labels such as “Fragile” and “Keep Dry.”

7. Vertical storage: If possible, packed doors should be stored vertically to avoid stress concentrating on one point.

8. Inspection: After completing the packaging, conduct a final inspection to ensure that all protective measures are in place and the packaging is intact.

9. Packing: For extra protection, packed doors can be placed in cardboard or wooden boxes.

10. Transportation preparation: Make sure the packaged door is placed firmly on the transportation vehicle to avoid movement and collision.

What we do

Product display

Crafting Elegance: Where Style Meets Substance in Every Detail

01

02

03

04

05

06

Precautions

Package Inspection: Upon opening the package, inspect all components for damage during transit. Missing or damaged parts can affect the door’s integrity and appearance.

Correct Assembly: Follow the manufacturer’s instructions for joining the frame accurately to ensure structural stability and proper door operation.

Stable Foundation: When standing the frame, make sure it is level and plumb. An uneven frame can lead to issues with door alignment and closing.

Secure Installation: Confirm that the frame is securely fastened to the wall opening with appropriate fixtures. Inadequate fixation can result in a safety hazard.

Sealant Application: Install rubber seal strips correctly to provide insulation and protection from water and air leaks, which could otherwise lead to energy loss and damage.

Door Leaf Alignment: Ensure that the door leaf is properly installed within the frame, with even gaps on all sides for smooth operation and to prevent sticking.

Architrave Fitting: Fit the architraves carefully to cover the gap between the frame and the wall, preventing drafts and enhancing the door’s appearance.

Lock Mechanism: Install the lock mechanism precisely as misalignment can compromise security and functionality.

Finishing Touches: After sealing with glue, clean any excess or spills immediately to prevent damage to the door’s finish and to maintain a clean, professional look.